Pesticide Drift Series: Using Buffers to Reduce the Impact of Spray Drift

ID

ENTO-454NP

Introduction

Pesticide spray drift can cause issues for growers and their surrounding community. As a pesticide applicator it is your responsibility to prevent the offsite movement of pesticides. One way to reduce pesticide spray drift is through the use of buffers.

What Is Drift?

Pesticides sprayed on crops and other sites can drift. Drift is the uncontrolled movement of pesticides through the air away from a target site. Drift is largely a problem with liquid pesticides but can also occur with dry formulations. You can manage pesticide drift with knowledge and responsible application practices.

Managing Drift

Many factors impact the drift potential of a pesticide application. With liquid formulations, drift potential depends on droplet size. Refer to Droplet Chart/Selection Guide (Virginia Cooperative Extension [VCE] publication 422-031) to learn more about droplet size. Since droplet size is determined by which nozzle you choose, nozzle selection is an important tactic in managing drift. Refer to Nozzles: Selection and Sizing (VCE publication 442-032) to learn more about nozzles. Other factors that affect drift include pesticide selection and formulations, application equipment, weather conditions, etc. To understand more about drift and how to manage it, refer to Pesticide Drift Series: Understanding and Controlling Pesticide Drift (VCE publication ENTO-452NP).

Drift and Sensitive Areas

Drift can occur anywhere. When it becomes a problem, it is usually associated with areas where there are people, other nontarget animals, or valuable plants. Examples of sensitive areas include, but are not limited to, residential areas, schools, healthcare facilities, and wildlife refuges.

How Do You Protect Sensitive Areas?

There are a number of best management practices (BMPs) that pesticide applicators, landowners, and managers can use to prevent pesticide drift from affecting sensitive areas. One method is to create a buffer between the application site and the sensitive area. Buffers are discussed in detail below. For additional BMPs, refer to Pesticide Drift Series: Protecting Sensitive Areas From Pesticide Drift (VCE publication ENTO-453NP).

Mitigate Drift With Buffers

Buffers are areas where no pesticide application should occur and are designed to intercept drift. Buffers should be relatively wide areas to allow spray materials to settle, and will be more effective if vegetation is present. Most sprayers (ground and aerial) have defined distances that spray can travel after release. These data are specific to crop and sprayer type. Knowing them can help you determine an appropriate size for your buffer. Check your equipment manual for spray release specifications, and always consult your pesticide product label to see if it offers any information on buffers.

Types of Buffers

Two types of buffers can be used to intercept spray drift: buffer zones and wind buffers. Buffer zones are strips of land that separate pesticide-treated areas from untreated areas. Buffer zones act as barriers to keep pesticides out of nontarget areas. Some pesticide labels may specify required buffer zones when using a particular product. Wind buffers consist of different types of perennial vegetation and are designed to lower wind speed and/or catch off- target spray on their surfaces. Windbreaks, cross wind trap strips, and herbaceous wind barriers are three types of wind buffers.

A windbreak is a barrier, such as a line of trees located along or within field borders of cropping systems. This type of wind buffer is designed to reduce spray drift by decreasing wind speed (fig. 1). Depending on wind direction and placement, windbreaks are also capable of intercepting spray drift. Windbreaks can be a single row or multiple rows of established trees (fig. 2).

Other wind buffers include cross wind trap strips and herbaceous wind barriers. These wind buffers are located within field borders of cropping systems and should be planted perpendicular to the prevailing wind direction. Cross wind trap strips consist of strips of herbaceous vegetation (i.e. non- woody plants). Herbaceous wind barriers consist of narrow rows of tall grasses, which can reduce wind speed. These wind buffers can catch airborne particles carrying pesticides, and help reduce wind erosion and nutrient loss in cropping systems.

General Guidelines for Implementing Buffers

- There are several desirable characteristics for buffers intended to intercept spray drift. Efficiency of buffers will vary depending on their size and density, the lay of the land, and weather conditions. Basic guidelines and considerations include:

- When positioning a buffer, consider sunlight and the prevailing wind direction.

- Consider using a mixture of vegetation and open areas or multiple rows of buffers (fig. 2). This can help break up wind patterns and/or increase overall surface area to make a buffer more effective.

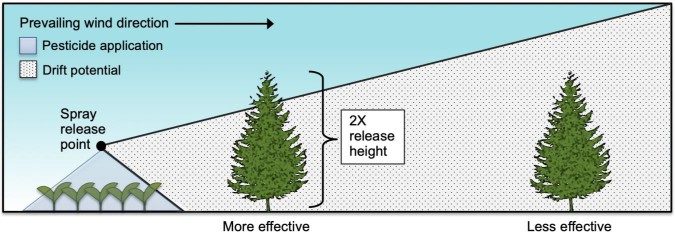

- Place buffers as close to the spray release site as possible. Buffers should be at least two times the release height of the sprayer used in your cropping system (fig. 3).

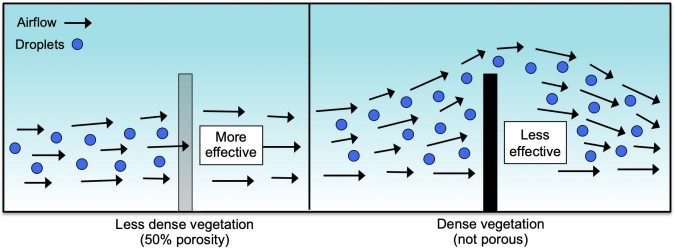

- Design buffers to be semi-permeable (50% porosity) – you should be able to see through the buffer. This allows air to flow through and filter pesticide particles (fig. 4).

- Avoid solid buffers. These can force drift over top of the buffer (fig. 4).

- Buffer vegetation should consist of tall grasses and tree and shrub species suited to your locality. Desirable plant characteristics include:

- Thin, needle-like leaves.

- Numerous small branches.

- Large leaves covered in small hairs.

- Rough foliage surfaces.

References

Grisso, R. 2019. “Droplet Chart/Selection Guide.” Virginia Cooperative Extension 442-031.

Grisso, R., S.D. Askew, and D. McCall. 2019. “Nozzles: Selection and Sizing.” Virginia Cooperative Extension 442-032.

McCoy, T. 2021. “Pesticide Drift Series: Understanding and Controlling Pesticide Drift.” Virginia Cooperative Extension ENTO 452-NP.

Parson, R. 2021. “Pesticide Drift Series: Protecting Sensitive Areas From Spray Drift.” Virginia Cooperative Extension ENTO-453NP.

Additional Resources

Bagdon, J., R. Parker, T. Gilding, N. Poletika, and

D. Fawcett. 2000. “Conservation Buffers to Reduce Pesticide Losses.” United States Department of Agriculture Natural Resources Conservation Service and the United States Environmental Protection Agency Office of Pesticide Programs.

Deveau, J. S. T. 2012. “Vegetative Barriers to Pesticide Drift.” Ministry of Agriculture, Food and Rural Affairs. Ontario, Canada.

Hoekstra, P. F. and C. Hannam. 2017. “White Paper on Vegetative Buffers.” Syngenta Canada Inc. and Synthesis Agri-Food Network. Guelph, Ontario.

Primary Industries Standing Committee. 2002. Spray Drift Management: Principles, Strategies, and Supporting Information. Victoria, Australia: CSIRO Publishing. 83 p.

“The Value of Buffers for Pesticide Stewardship and Much More.” 2013. Syngenta Inc.

This publication was adapted by Stephanie Blevins- Wycoff, Extension Associate, Virginia Tech Pesticide Programs, from “Control Your Drops: Control Your Drift” by M. J. Weaver (Virginia Tech Pesticide Programs) and W. W. Surles (Virginia Department of Agriculture and Consumer Services, Office of Pesticide Services), October 2005. This factsheet is not a step- by-step guide to drift management and is not a substitute for pesticide label directions. The methods and materials described here should be tailored to your locality. Always consult your local Extension agent when developing a plan for drift management.

Virginia Cooperative Extension materials are available for public use, reprint, or citation without further permission, provided the use includes credit to the author and to Virginia Cooperative Extension, Virginia Tech, and Virginia State University.

Virginia Cooperative Extension is a partnership of Virginia Tech, Virginia State University, the U.S. Department of Agriculture (USDA), and local governments, and is an equal opportunity employer. For the full non-discrimination statement, please visit ext.vt.edu/accessibility.

Publication Date

June 22, 2021